The common anode connection is the current flowing from the PCB to the lamp beads, to R, G, B (red, green, blue) unified power supply, to incur the circuit forward voltage drop becomes large.Ĭommon cathode, as cited above, it will be separate to R, G, B (red, green, blue) to provide current voltage. G, B (red, green, blue) lamp beads required by the best working voltage and current is not the same, so that the current will first go through the lamp beads and then to the IC cathode, the forward voltage drop will be reduced, the on-state internal resistance will become smaller.Ĭommon cathode power supply method, as mentioned above, is by the current first through the lamp beads, and then to the IC cathode, so that the forward voltage drop becomes smaller, the conductive internal resistance also becomes smaller. “Common Cathode”, refers to the common cathode power supply, in fact, is a led display energy-saving technology, refers to the use of common cathode way to power the led display, that is, the use of led beads R, G, B (red, green, blue) to separate the power supply, accurate respectively for R, G, B beads to allocate current voltage, due to R, G, B (red, green, blue).

Only now, as the industry chain and technology products continue to mature and stabilize, and the cost decreases, it really makes the common cathode rgb led display into the public view. In fact, “common cathode” is not a brand-new technology, some of the industry’s screen enterprises in the early years of “common cathode technology indoor small pitch products” has been widely used in national key projects, and now with the industry chain and technology products continue to mature, stable, as well as cost reduction. LED display using common cathode technology, its energy-saving effect can reach 30% to 75%, greatly reducing the power consumption, and can save a lot of electricity expenses every year. When it runs in reverse, the colours will be reversed (ie red at the front and white at the rear).Conventional common led display has been through the years, has constituted a stable industry chain, driving the application of led display, with the development of the economy, the market requirements for led display size is getting larger and larger, using conventional led display to splice the large screen will have a lot of power consumption, every year to pay a lot of electricity costs. When the loco runs forward, the front LED will glow white and the rear LED will glow red.

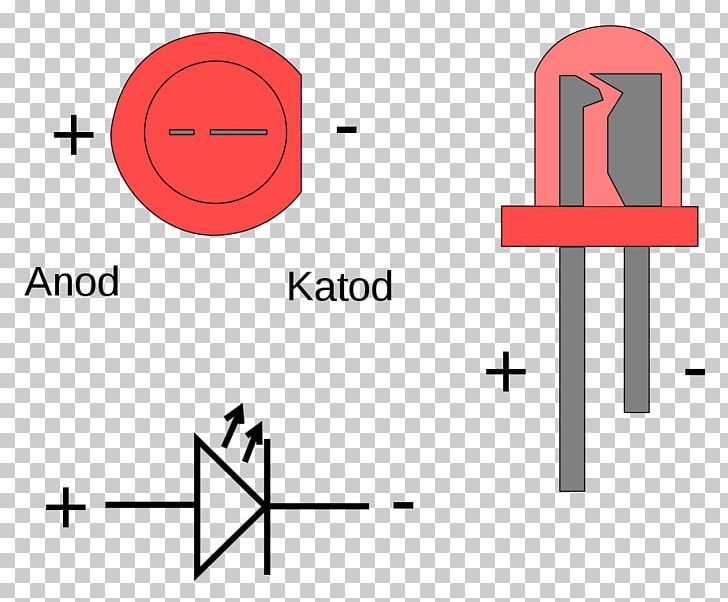

If using two LEDs (one for the front of the loco and the other for the rear), then the LEDs can be connected as below. This makes it more suitable for switching with the output pads from the RCT/Deltang receivers. The two internal LEDs share the middle leg (cathode - negative) and the LED is made to glow one colour by connecting one leg to the positive supply and it will glow the alternative colour by disconnecting the first leg and then connecting the second leg to the supply. The type of bi-colour LED which is most useful for use with RCT/Deltang receivers is the one with three legs. Bi-colour LEDs generally come in two types of packages - those with two legs and those with three legs.īi-colour LEDs with two legs are energised by reversing the input polarity - connect the two leads one way round on the battery supply and it will glow with one colour, connect it the other way round on the battery and it will glow the second colour.

0 kommentar(er)

0 kommentar(er)